Your cart is currently empty!

Patti P. Phillips and Jack J. Phillips

Abstract

Purpose – The purpose of this study is to illustrate how a combination of three motivational forces can

deliver superior team performance in an unlikely setting. Because motivation is the key to the success of

talent, exploring ways to motivate employees and teams has been at the forefront of behavioral research.

Design/methodology/approach – This paper focuses on the combination of three approaches: the use

of an improved engagement system, enhanced team development and cohesiveness and the use of

monetary incentives for recognition and achievement.

Findings – This combination of concepts delivered superior team performance in an unlikely setting.

Originality/value – This paper presents a program uniquely designed to motivate a team of employees

using multiple approaches. The program delivered outcomes benefiting the organization’s bottom line

while also rewarding employees and enhancing the team’s engagement.

Keywords – Performance, Employee engagement, Benefits, Learning and development, Productivity,

Rewards

Paper type – Case study

Background research and theory

Because motivation is the key to the success of talent, exploring ways to motivate employees

and teams has been at the forefront of behavioral research. This article focuses on the

combination of three approaches: the use of an improved engagement system, enhanced

team development and cohesiveness and the use of monetary incentives for recognition and

achievement. This combination of concepts delivered superior team performance in an

unlikely setting.

Engagement

Few topics have emerged as important as employee engagement in organizations. Employee

engagement has been built on a host of previous approaches to improve the employee

experience, beginning with employee satisfaction as the organizations focused on how to

make employees “happy” with their pay, the job, supervisor, coworkers and career. Although

important for attraction and retention of employees, satisfaction did not necessarily motivate

employees to improve the organization and drive performance. The concept morphed into

organizational commitment, which focused on getting employees more attached to,

concerned about and identified with the organization. This was further refined into employee

engagement, which was intended to have employees more involved in the decisions effecting

their work, attached to goals for which they are accountable, take more responsibility for their

work and the outcomes and share information and work as a team. In short, employee

engagement provides the motivational effect that drives productivity, quality, safety, sales and

client satisfaction, to name a few.

Focus on teams

Most organizations use integrated teams, and team members support each other and

produce more than the sum of the individuals. For teams to work properly, there must be

respect, shared responsibilities for the team and information shared within the team. If they

share a common goal, the performance is enhanced. The focus must be for the good of the

team and not necessarily for the good of the individuals.

Gainsharing

The gainsharing process is a system of management that includes financial measurement and

feedback to monitor company performance and distribute those gains in the form of bonuses

to employees. It is a focused involvement system to eliminate barriers of improved

performance. As performance improves, employees share financially in the gain (Masternak,

2009). Gainsharing systems vary widely in terms of their design and the degree to which they

are integrated into the regular operating systems of organizations.

Motivation

Motivational factors can vary widely depending on the nature of the work, the experience of

the employees, the type of organization and the structure of the organization. Depending on

which research you review, motivational factors will have some differences but usually share

some common themes:

- providing recognition for accomplishment;

- encouraging achievement at work;

- treating employees with respect;

- empowering employees to take action;

- providing feedback and coaching;

- building trust with employees;

- involving employees in decisions;

- setting clear expectations; and

- providing routine and transparent communication (Heathfield, 2019).

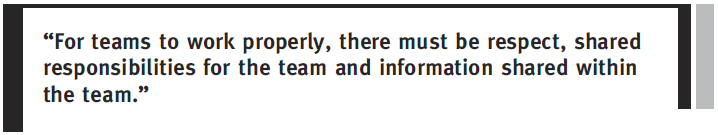

This article presents a project that combines the elements of an improved engagement

system with a focus on team bonus, with a process called gainsharing, and builds on

motivational aspects to produce superior performance (Phillips et al., 2016). Because

this program represented a significant change in the way employees work and are

rewarded, the top executives wanted a thorough evaluation with a pilot group involving

six locations, including an return on investment (ROI) calculation. If successful, the

program could be implemented in other plants. The ROI Methodology, the most used

evaluation system in the world, was used to evaluate the program. The steps of the

methodology are illustrated in Figure 1.

![]()

Organizational setting, solution and results

National Crushed Stone (NCS) is a leading firm in the crushed stone industry, with more

than 300 locations in many geographic areas. The crushed stone industry is highly

competitive; profit margins are narrow and cost control is everything. Companies in this

industry are constantly seeking ways to control costs to gain a competitive advantage

in the marketplace.

Step 1 – Start with why: align programs with the business

There were some concerns that the costs at NCS were not as low as they could be, although

they were among the lowest in the industry. Some costs were fixed and not under the control

of the stone quarry team. However, many costs could be controlled. The executives wanted an

innovative approach to control costs, perhaps using a behavioral approach. Employee

turnover was higher than desired, about 18 per cent, annually. Also, unplanned absenteeism

was high, about 7 per cent. A focus of engagement, teamwork and motivation should improve

these two measures. In summary, the business measures aligned with this problem were costs

per ton, voluntary turnover and unplanned absenteeism.

Step 2 – Make it feasible: select the right solution

Based on engagement studies in the literature, if employees were engaged in quarry

operations, taking a very strong interest in maintaining the equipment, working smarter and

operating efficiently, the costs could be lower, perhaps even significantly so. The talent

development team suggested a simple engagement survey and proposed that if employees

became more engaged, they would take more interest in their jobs, try to be more efficient,

take better care of equipment and the facility and even make suggestions for improvement.

However, the company culture was not open to employees accepting more

responsibility, making recommendations and being more involved in making decisions.

To implement this plan, NCS would have to change its culture. However, this does not

happen just by decree, discussion, meeting, memo or policy – it comes from changing

the mindset of the organization while adjusting job descriptions and encouraging

employees to open up and be engaged. To help augment this change, the quarry

superintendents assumed the role of plant managers, with the additional expectation of

having a more involved and engaged workforce.

In early discussions, it was suggested that a portion of the cost savings be shared with the

employees using the motivational effect of rewards. Using a concept called gainsharing, the

decision was made to share half the gains in cost reductions with employees, providing a bonus for exploring options to lower costs. Together, the three actions should provide a

solution to improve costs per ton, voluntary turnover and unplanned absenteeism.

Step 3 – Expect success: design for results

The new system was planned for implementation in six locations that represented typical

NCS plants. A comparison group of six locations was selected to serve as the control

group. The complete process, which would comprise several stages, was developed

during a two-month period using an external consultant and the part-time assistance of two

internal staff members. A revised engagement instrument based on the engagement issues

was administered just before the program was launched with the six pilot plants. A postsurvey

would be administered three months later.

The success of the new system is defined at the impact level in a system that has five levels of

outcomes: reaction, learning, application, impact (tangible and intangible) and ROI. Specific

objectives were developed at each outcome level and provided to all stakeholders so they

could design for each level of outcome. Particular emphasis was placed on impact.

Specific cost measures and other impacts would be monitored at each plant before and

after the program, and these data would be compared between plants. This control group

arrangement involved identifying six other crushed stone plants to compare with the six

plants destined for implementation.

This approach should ensure that the results achieved were directly related to the new

system. The actual cost of the system would be compared with the monetary value of the

benefits to develop an ROI. To be conservative, one year of monetary benefits would be

obtained and compared with the fully loaded costs of the program.

Step 4 – Make it matter: design for input, reaction and learning

The engagement survey, administered as part of the needs assessment, was the

beginning point to determine what issues should be addressed. After input from

the plant managers, senior executives and employees, coupled with a review of the

literature on engagement, a new definition of engagement was developed. This

detailed six items employees need from their jobs, five items employees must see in the

work setting and seven things employees must do to take a more active role and make

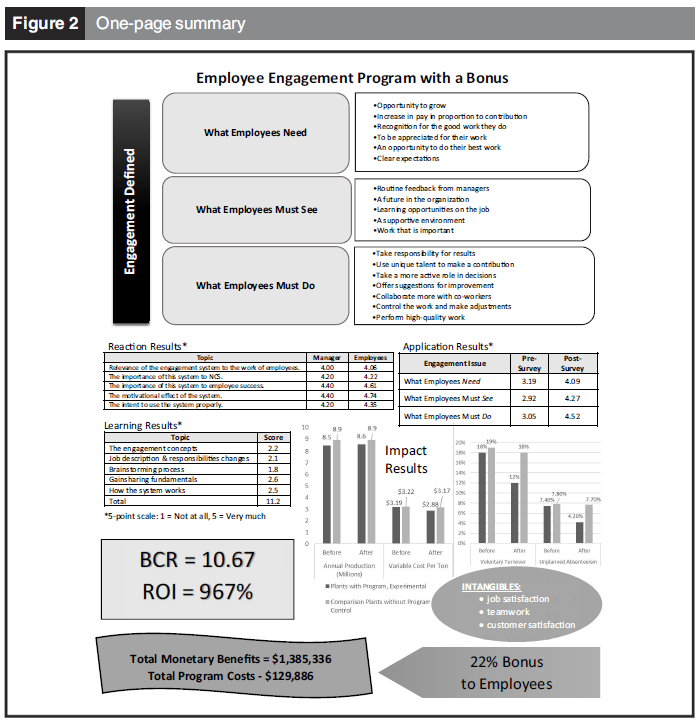

improvements leading to the desired impact, as shown in Figure 2.

Employees must learn about the new engagement program and compensation system and

react favorably to it. Although a positive reaction was assumed, employee feedback was

obtained using a one-page questionnaire and included reactions from the plant managers on

the same set of measures. Both employees and plant managers provided reactions that

exceeded the expectations, which were critical for success later.

For learning, a simple true/false and multiple-choice test was administered, using three

questions about each part of the program, for a total of 15 points for perfect scores. The

total result for this level from the employees was 11.2, which exceeded the goal of 70

per cent minimum score (10.5). The reaction and learning results are shown in Figure 2.

Step 5 – Make it stick: design for application and impact

It is important to capture data about how employees are participating in meetings,

taking a more responsible role, accepting accountability for results and sharing

information freely with others. A survey was administered three months after the

program, which revealed significant and impressive improvements in the overall

categories. Data were collected from the employees and their plant managers. Data

from the managers were based on observation, whereas the data from the employees

were collected using a questionnaire to determine their perception of what they were

actually doing. Application results are shown in Figure 2.

It is important to clearly understand the impacts of the program. For both the experimental

and control groups, the cost per ton for each cost category was monitored, along with the

annualized turnover rate and the unplanned absenteeism rate.

Step 6 – Make it credible: isolate the effects of the program

Comparing the experimental group with the control group showed a dramatic improvement in

the impact measures. The total employment and production remained similar between the control and experimental plants, as desired. The cost per ton for the variable costs showed a

dramatic improvement for the experimental plants, with a reduction of 31 cents per ton.

However, because there was also a 5-cent-per-ton reduction in the plants without the system,

this 5 cents per ton must be subtracted from the 31 cents to yield a 26-cent improvement.

The same approach was taken for volunteer turnover. The experimental plants saw a

significant reduction from 18 to 12 per cent (6 per cent). Because the control plants also saw a

1-per cent reduction, that 1 per cent is subtracted. Thus, the program saw a 5-per cent

improvement. Unplanned absenteeism saw a dramatic reduction from 7.4 to 4.2 per cent (3.2

per cent) for the experimental plants. There was a slight reduction (0.1 per cent) in the control

plant, which was also subtracted to give the overall improvement (3.1 per cent).

From all indications, nothing unusual was happening in the six plants that was not occurring

in the comparison group (such as a sudden market shift, weather issues, a change in plant

manager or other factors). So, it appears that these plants were matched well and were

consistent throughout the year-long study.

Step 7 – Make it credible: convert data to monetary value

Converting the data to money was relatively easy because the monetary values were

already in the organization. Production costs, expressed in money as cents per ton, is the

principal measure connected with the project. The HR data from external studies suggested

that for this mix of employees, the voluntary turnover cost would be about 50 per cent of

annual pay, and management agreed to this value before the system was implemented.

The absenteeism cost was straightforward, and the sponsors agreed with the estimated

cost from the payroll function, $160 per day.

The 26-cent-cost-per-ton improvement in total production (8,600,000 tons) gave a bonus

pool of $2,236,000 to be spilt equally with employees and the company, yielding a bonus of

$9,395 annually for the employees. This, indeed, is a powerful motivator. In addition, it

represents a huge amount of savings directly to the company’s bottom line as the monetary

benefit for this program: a total of $1,118,000.

Turnover costs were calculated similarly, with this program preventing 5 per cent

turnover, which would annualize to yield six turnovers prevented for the company. A

turnover cost was provided by HR, which was 50 per cent of annual pay. For these

employees, this was $20,956 for each turnover. For six turnovers, this was $125,736.

Absenteeism costs were quite straightforward, with a 3.1 per cent reduction as a result

of this program. This represented 885 days. The cost per day is $160, which was the

average daily wage rate. The total cost is $141,600. The total monetary benefit is

$1,118,000 þ $125,736 þ $141,600 = $1,385,336.

Step 8 – Make it credible: capture costs of project

The total cost for the program was calculated by various categories and prorated just to the

sample size. The total program cost was $129,886.

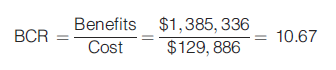

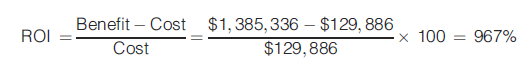

Step 9 – Make it credible: calculate return on investment

The benefit–cost ratio (BCR) and ROI were calculated and are shown. For every dollar

invested, there was $10.70 in benefits, which is extremely high by any BCR calculation:

In addition, the ROI was calculated to be 967 per cent, which means that for every dollar invested

in this program, another $9.67 was returned after the dollar is recovered. This is significant:

Step 10 – Make it credible: identify intangible measures

Although measurable and convertible to monetary values in some cases, the intangibles

were considered significant but were not used in the ROI analysis. Several intangible

benefits were identified and connected to the project, including job satisfaction, teamwork,

the number of loads of stone rejected by the customer and the amount of plant downtime.

Step 11 – Tell the story: communicate results to key stakeholders

The results are impressive, clearly showing all stakeholders the value of investing in

engagement and motivation and exceeding the expectations of all involved. Figure 2

presents a one-page summary of the program results.

Step 12 – Optimize results: use black box thinking to increase funding

The vice president of operations was amazed at the reduction in cost and made the

recommendation to set the next budget at the previous level, adjusted for the producer

price index. If the team maintains this level of performance, their bonus will increase as the

producer price index increases. If costs are reduced further, the bonus will be even greater.

Also, the decision was made to implement this system in the other plants. Some

adjustments were made to make the program better.

Conclusion

This article presents a program uniquely designed to motivate a team of employees using

multiple approaches. The program delivered outcomes benefiting the organization’s bottom

line while also rewarding employees and enhancing the team’s engagement.

References

Heathfield, S.M. (2019), “Want to encourage and inspire employee motivation?”, available at: www.

thebalancecareers.com/what-is-employee-motivation-1918108

Masternak, R.L. (2009), “Gainsharing or profit sharing: the right tool for the right organization

compensation”, HR-Guide.com, available at: https://hr-guide.com/data/G44301.htm

Phillips, J.J. and Phillips, P.P. (2016), “Measuring ROI in employee engagement with a bonus”, in Phillips,

J.J., Phillips, P.P. and Ray, R.R. (Eds), Measuring the Success of Employee Engagement: A Step-by-Step

Guide orMeasuring Impact and Calculating ROI, ATD Press, Alexandria, VA.

Phillips, P.P., Phillips, J.J., Paone, G. and Huff Gaudet, C. (2019), Value for Money: How to Show the

Value for Money for All Types of Projects and Programs in Governments, Non-Governmental

Organizations, Nonprofits, and Businesses, Wiley-Scrivener, Hoboken, NJ.

Corresponding author

Jack J. Phillips can be contacted at: jack@roiinstitute.net